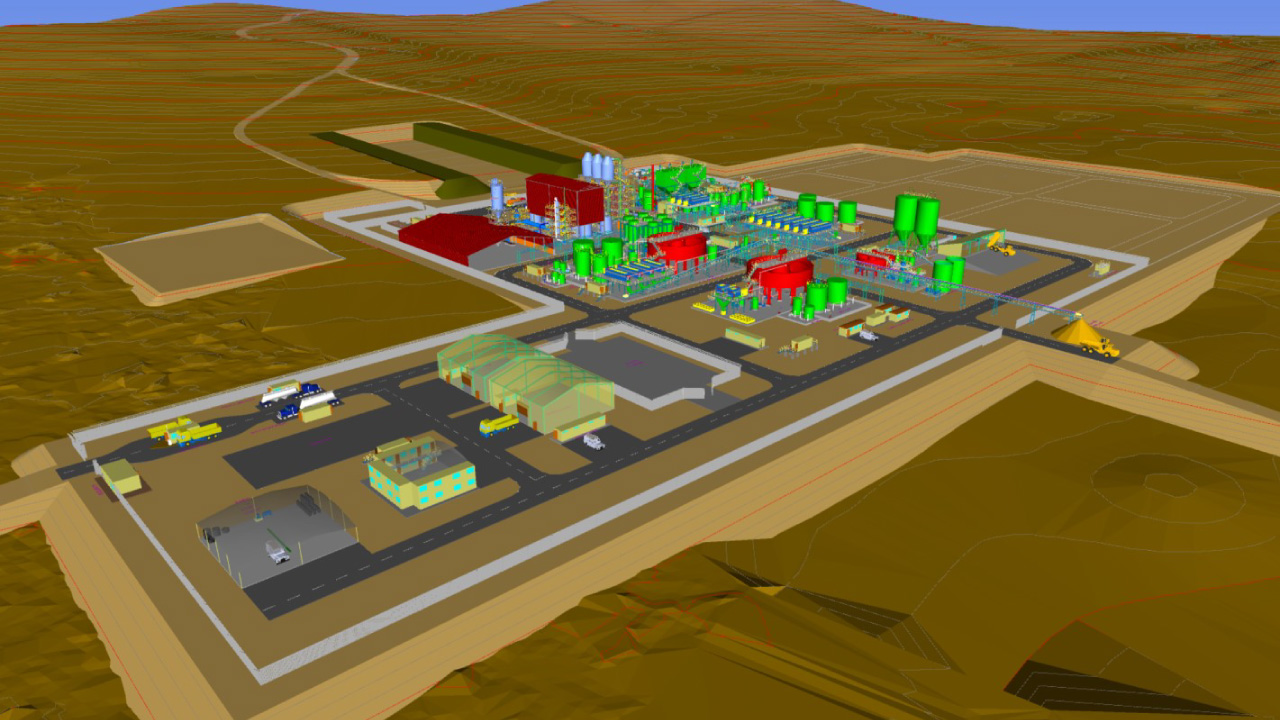

Giyani Metals Corp. is a battery development company that is currently creating a portfolio of high quality mining and metals processing assets within the Kanye Basin, Botswana. Within this area is the K. Hill, Giyani’s flagship project that Tetra Tech has been supporting with since 2019.

HPMSM is a chemical compound used extensively in batteries for electric cars, energy storage solutions and numerous other renewable technologies. The process of extracting manganese from ore can be costly and the sustainability of conventional processes questionable owing to energy intensive methods of production.

Tetra Tech was brought onboard to produce HPMSM from low grade ore using more cost effective, environmentally friendly methods of production compared with traditional methods. Using our Leading with Science® approach this was not only achieved but the process employed was less energy intensive significantly reducing the carbon footprint of the project.

Innovation

The carbon footprint was reduced by replacing the conventional carbothermic pre-reduction process and producing HPMSM directly without first having to produce Electrolytic Manganese Metal (EMM) or Electrolytic Manganese Dioxide (EMD). The carbothermic reduction process was replaced with a sulphur dioxide reduction process followed by a sequential solution purification process, to produce HPMSM directly from the purified sulphate solution. Another major feature of the project was the inclusion of a large PV array providing 4.5 MW of solar power, which reduced the carbon footprint even further.

Results and Benefits

The final HPMSM product achieved purity greater than 99.97%, which equates to less than 300 parts per million total impurities, qualifying the product as battery grade.

A major consideration for end clients is the carbon footprint of the entire raw materials supply chain. These developments have shown that Giyani will have one of the lowest carbon footprints of any HPMSM manufacturer in the world.

Connect with us. Reach out to our experts.